What is Zinc Sulfide?

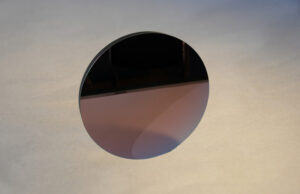

Zinc sulfide (ZnS) is widely used in the production of infrared optical components such as infrared windows, fairings and lenses. It has the characteristics of high purity, insoluble in water, moderate density, and easy processing.

Zinc sulfide (ZnS) has good refractive index uniformity and consistency, and has good image transmission performance in the 8-12μm band, but some parts begin to absorb after 10um. The transmittance is higher in the mid-infrared band, and as the wavelength becomes shorter, absorption and scattering increase.

Zinc sulfide (ZnS) has strong resistance to harsh environments, high hardness and twice the breaking strength of zinc selenide (ZnS).

Tough front optics for zinc sulfide (ZnS) thermal imaging systems for use in the infrared window and thermal band (8 to 14 μm).

Zinc Sulfide Uses

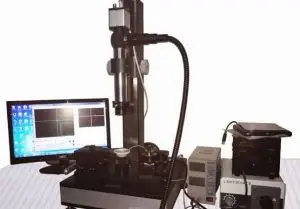

Single crystal zinc sulfide (ZnS) is available but less common. Scattering is very low in the commonly used spectral range. It can be used as a high-power laser device while strictly controlling the bulk absorption and internal structural defects of the material, while using minimally damaging polishing technology and higher optical quality coating processes.

Zinc sulfide (ZnS) oxidizes significantly at 300°C, shows plastic deformation at about 500°C, and dissociates at about 700°C. For safety reasons, zinc sulfide windows should not be used above 250°C in normal atmospheres.

Zinc Sulfide Price

The price of zinc sulfide (ZnS) varies globally based on purity, grade (e.g., multi-spectral or IR-grade), and application.

Standard optical-grade ZnS typically ranges from $300 to $1,500 per kilogram, while high-purity, multi-spectral grades can exceed $3,000 per kilogram.

Used in infrared optics, military systems, and thermal imaging, ZnS demand is driven by its unique transmission properties and durability. Market factors like raw material costs, production methods, and regional supply chains also influence pricing.

| Diameter | 3mm-70mm |

| Edge Thickness | ≥0.7mm |

| Medium Thickness | ≥1mm |

| Angle Processing Range | 0°~65° |

| Lost Height Processing Range | ≤21mm |

| Caliber and Medium Thickness Ratio | within 17 |

| Pv | 0.1μm |

| Ra | 4nm-10nm |

| △N | 0.3-1 |

| Coating | AR coating, reflective film, metal film |

Bote Zinc Sulfide (ZnS) lenses and Zinc Sulfide (ZnS) windows are also available with AR coatings upon specific request.

Please use extreme caution when handling, fitting and cleaning zinc sulfide lenses and, for your safety, follow all appropriate precautions, including wearing gloves when handling these lenses and washing your hands thoroughly after handling.