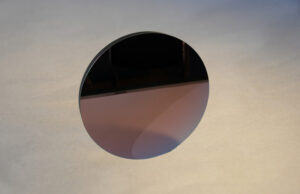

As a key component in the optical field, ZnSe selenide lenses are favored for their excellent optical properties, especially extremely high transmittance in the infrared spectrum. They are an indispensable component in various optical systems, not only in infrared imaging and laser It has been widely used in systems and has performed well in fields such as thermal imaging and infrared sensors.

Our zinc selenide lenses are available in a variety of shape options, including spherical plano-concave, plano-convex, meniscus or aspherical shapes to meet the design requirements of different optical systems. Whether in infrared imaging systems, laser components or infrared sensors, zinc selenide lenses provide precise optical performance for your optical system.

Zinc Selenide Properties

Zinc selenide (ZnSe) is a relatively soft material that is easily scratched and is not recommended for use in harsh environments because its Knoop hardness is only 120.

Special care should be taken when handling zinc selenide as it is a toxic substance, apply even pressure and wear latex finger cots or gloves to prevent contamination.

Znse Refractive Index

Primary zinc (ZnSe) is an important optical material whose refractive index changes at different wavelengths.

In the visible range, the refractive index of primary zinc is usually between 2.4 and 2.5.

The inductance may be different in the infrared spectral range. In addition, calcified inductors are also affected by temperature.

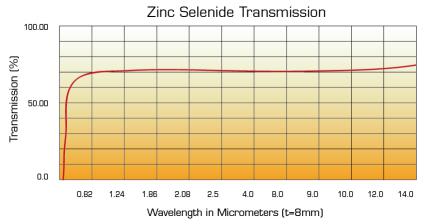

Light Transmission of Zinc

The light transmittance of zinc depends on the specific material.

For example, the transmittance of ZnSe coated with anti-reflection coating is about 97% in the 2~13um band, while ZnS can also be maintained at around 70%.

These materials are widely used in the fabrication of infrared windows, fairings and infrared optical components

| Znse Window&Lens | |

| Diameter | 3mm-70mm |

| Edge Thickness | ≥0.7mm |

| Medium Thickness | ≥1mm |

| Angle Processing Range | 0°~65° |

| Lost Height Processing Range | ≤21mm |

| Caliber and Medium Thickness Ratio | within 17 |

| Pv | 0.1μm |

| Ra | 4nm-10nm |

| △N | 0.3-1 |

| Coating | AR coating, reflective film, metal film |

For High-power Applications

The key is to carefully control the material’s volume absorption and internal defect structure, employ minimally damaging polishing techniques, and use higher-quality optical thin-film coatings. The material’s absorption was verified by carbon dioxide laser vacuum calorimetry.

Bote Znse Windows and Lenses

The conventional polishing range for zinc selenide (ZnSe) optics is 5 to 300mm. The dimensions of diameter and thickness can be manufactured according to customer requirements. Zinc selenide (ZnSe) is non-hygroscopic and chemically stable unless treated with strong acid. It can be used safely in most industrial, field and laboratory environments.

Bote mainly produces zinc selenide windows and lenses

Zinc Selenide Window: The size requirements can be based on the actual needs of the customer for lightweight, and higher precision can also be customized according to the customer’s requirements.

Zinc selenide lens: Types include plano-convex, plano-concave, biconcave, biconvex, meniscus, and aspherical lenses. The size can be customized according to customer requirements.

Application areas: national defense weapons, thermal imaging cameras, infrared thermometers, night vision devices, etc.