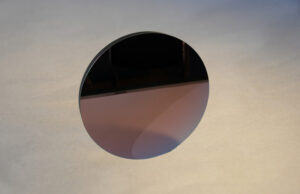

Waveplates, also known as retarders, are optical components used to alter the polarization state of light passing through them. They are made from birefringent materials, such as quartz or calcite, which have different refractive indices along two perpendicular axes. This property allows waveplates to introduce a phase shift between the orthogonal polarization components of the light. Depending on the thickness of the waveplate, this phase shift can be designed to be a quarter-wave (λ/4), half-wave (λ/2), or any other specific fraction of the wavelength, effectively converting linear polarization to circular polarization, or rotating the plane of polarization by a desired angle.

General Fabrication Specification

Waveplates are fabricated with precise control over material selection, thickness, and surface quality to ensure accurate phase retardation. The following table outlines typical specifications:

| Specification | Detail |

|---|---|

| Material | Crystalline quartz, Calcite, Magnesium Fluoride (MgF2) |

| Retardation Tolerance | λ/100 to λ/500 depending on application requirements |

| Waveplate Type | Zero-order, multi-order, achromatic |

| Diameter | 10 mm to 100 mm (custom sizes available) |

| Surface Quality | 20/10 S&D or better |

| Coating | Anti-reflective coatings (AR) for specific wavelength ranges |

| Parallelism | < 3 arcseconds |

| Clear Aperture | > 90% of the diameter |

Fabrication Process and Quality Control

The fabrication of waveplates involves the precision slicing of birefringent crystals to the exact thickness required to produce the desired phase shift. After slicing, the surfaces are meticulously polished to achieve an optical-grade finish, minimizing any surface imperfections that could cause scattering or absorption of light. For certain applications, the waveplates may be assembled in pairs (composite or cemented waveplates) to achieve zero-order or achromatic performance, reducing sensitivity to wavelength variations and temperature fluctuations.

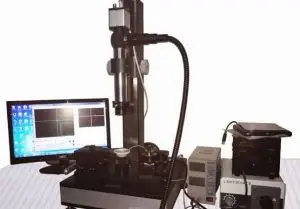

Quality control processes at Bote Optics include interferometric testing to measure the actual phase retardation introduced by the waveplate, ensuring it meets the specified tolerance. Surface quality is verified using a surface profiler, and the parallelism of the waveplate is checked with high-precision metrology tools to guarantee alignment accuracy.

Application

Waveplates are crucial components in various optical systems where control of the polarization state is necessary. They are widely used in laser optics, microscopy, telecommunications, and photonics research. For example, quarter-waveplates are commonly used to convert linearly polarized light into circularly polarized light, which is essential in optical isolators and polarization-sensitive imaging systems. Half-waveplates, on the other hand, are used to rotate the polarization direction of linearly polarized light, which is valuable in polarimetric measurements and polarization modulation applications.

Why Choose Bote Optics

Bote Optics offers waveplates with superior performance and reliability, tailored to meet the specific needs of our customers. Our waveplates are manufactured using state-of-the-art equipment and techniques, ensuring precision in phase retardation and surface quality. With a focus on innovation and quality, Bote Optics delivers optical components that excel in demanding environments, from high-power laser systems to sensitive imaging applications. Our commitment to customer satisfaction, combined with our expertise in optical engineering, makes Bote Optics the preferred choice for high-quality waveplates.