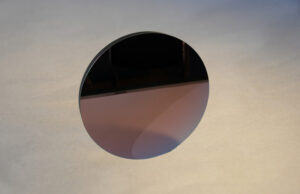

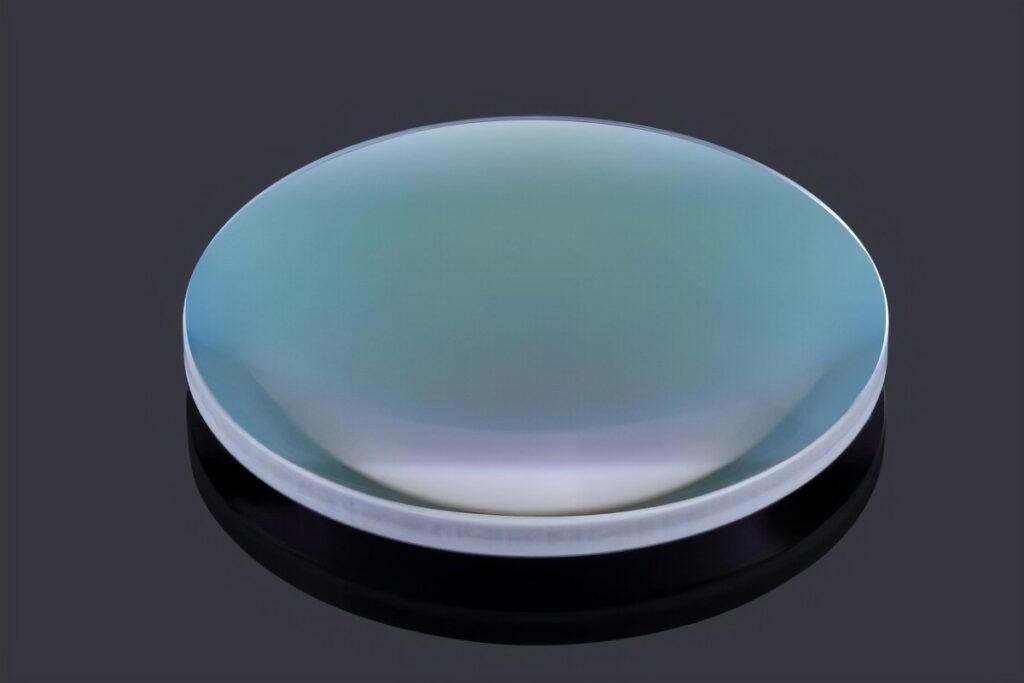

Sapphire lenses are made of single crystal material with aluminum oxide (Al2O3) as the main component. This material occurs in nature as corundum and is finely processed to create high-quality optical lenses.

Benefits of Sapphire

Hardness and wear resistance: Sapphire has extremely high hardness, second only to diamond, with Mohs hardness reaching level 9. This makes sapphire windows have excellent wear resistance and can remain clear for a long time in high-speed, high-load working environments, reducing the frequency of maintenance and replacement.

Light transmittance(sapphire ir transmission): Sapphire lenses have good transmittance in both visible and infrared light ranges. In the visible light range, its transmittance usually exceeds 80%; in the infrared range, especially in the near-infrared and mid-infrared bands, its transmittance can reach more than 90%.

Temperature resistance: Sapphire can maintain stable performance at temperatures up to 2000°C without deformation, softening or thermal expansion, ensuring stable light transmission efficiency in high temperature environments.

Good corrosion resistance: High resistance to acids, alkalis and some solvents, suitable for harsh environments.

Wide application adaptability: Due to the stability of its physical and chemical properties, sapphire lenses are suitable for many different application scenarios.

Application:

Laser system: Sapphire lenses can withstand the impact of high-power laser beams and are suitable for optical windows of lasers.

Optical sensors and instruments: protect sensors in harsh environments, ensure data accuracy, and are used in various precision optical instruments.

High-temperature and high-pressure equipment: In high-temperature and high-pressure processes, sapphire lenses can maintain a clear view for easy observation and monitoring.

Aviation and aerospace: Used in aircraft cockpit windows, etc., suitable for its high strength and weather resistance.

Architecture and automotive fields: It can be used to make large glass curtain walls, skylights, and side windows of high-end cars. It is favored for its high strength, aesthetics, and light transmittance.

Specification:

| Materials | Sapphire crystal (Al2O3) |

| Transmittance | 0.2-5.5um(Applicable to visible and infrared light) |

| Dimension Error | +0.0,-0.1mm |

| Thickness Tolerance | ± 0.2mm |

| Clear Aperture | > 90% |

| Parallelism | 3 points |

| Wavefront Distortion | λ per 25mm@633nm |

| Surface Finish | 40-20 |

| Bevel | < 0.25mm* 45° |

FAQ:

Q: Sapphire Lens Price?

A: The price of sapphire lenses varies globally based on factors like size, quality, surface accuracy, and customizations such as coatings.

Standard sapphire lenses typically range from $50 to $500 per piece, while large, precision-engineered, or custom-coated lenses can exceed $1,000.

Demand from industries like aerospace, medical devices, and optical systems also influences pricing. In regions like Asia, competitive manufacturing lowers costs, while high-precision markets in Europe and the U.S. may command premium prices.

When sourcing sapphire lenses, balancing cost with required specifications and supplier reliability is crucial.

A: Sapphire UV Transmission

Q: Sapphire is an excellent material for UV transmission due to its wide optical transmission range, spanning from UV to IR wavelengths. It offers high durability, exceptional thermal stability, and resistance to scratches, making it ideal for UV optics in harsh environments.

Sapphire’s low absorption and high transparency in the UV spectrum enable its use in scientific instruments, medical devices, and industrial applications. Its robust nature ensures consistent performance in extreme conditions, making it a preferred choice for precision UV transmission components.