What is Positive Meniscus Lens?

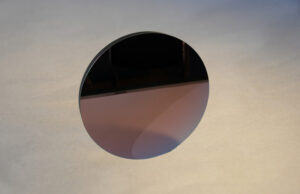

A positive meniscus lens is a type of meniscus lens(or plus meniscus lens). Its appearance is similar to that of a meniscus lens.

However, a meniscus lens consists of two spheres with small curvature radii and very small numerical differences.

A moon-shaped lens composed of three sides.

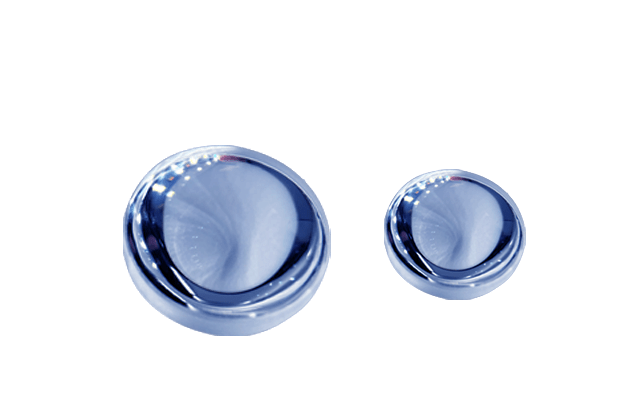

Meniscus Lenses for CO2 Lasers and Infrared Optical Systems Meniscus lenses reduce spherical aberration and produce minimal collimation focus of incident light. Positive meniscus lenses are used to reduce the focal length of another lens while maintaining the angular resolution of the optical assembly.

Its materials include BK7, UV fused silica, CaF2, and ZnSe, etc.

Features

A positive meniscus lens is composed of two curved surfaces with similar radii of curvature and has a positive focal length. Usually used to reduce the focal length of another lens, increase the numerical aperture and other related applications.

In order to reduce spherical aberration, when applying beam expansion or contraction or divergent collimated light, the light should be incident on the convex surface of the lens.

When used for convergent light collimation, the light should be incident on the convex surface of the lens.

Shoot on the concave surface.

Positive curvature lenses are primarily used to minimize spherical aberration. When combined with another decoy lens, a positive meniscus lens can reduce the focal length and increase the system numerical aperture (NA) without introducing significant spherical aberration.

When used to converge parallel light, the convex surface of the lens should be oriented in the direction of emission from the light source in order to minimize spherical aberration. Coated lenses are also widely used in visible light and near-infrared applications.

Application:

- Beam expander lens

- Imaging lens

- Converging lens

Specification

| materials | K9, N-BK7, JGS series UV fused quartz |

| Working range | 400 nm-700 nm (other bands can be customized) |

| Design wavelength | 546.1nm(n=1.519) |

| Focal length tolerance | ±2% |

| Shape tolerance | +0.0/-0.02mm |

| Thickness tolerance | ±0.02mm |

| Curved aperture | 3 |

| Plane flatness (aperture) | 1 |

| Curved surface local aperture | 0.5 |

| Eccentricity | ≤3 arcmin |

| Surface quality | In/[email protected] |

| Surface finish | US military standard 60-40 |

| Clear aperture | >90% |

| Bevel | <0.2X45 |