Description of the Components:

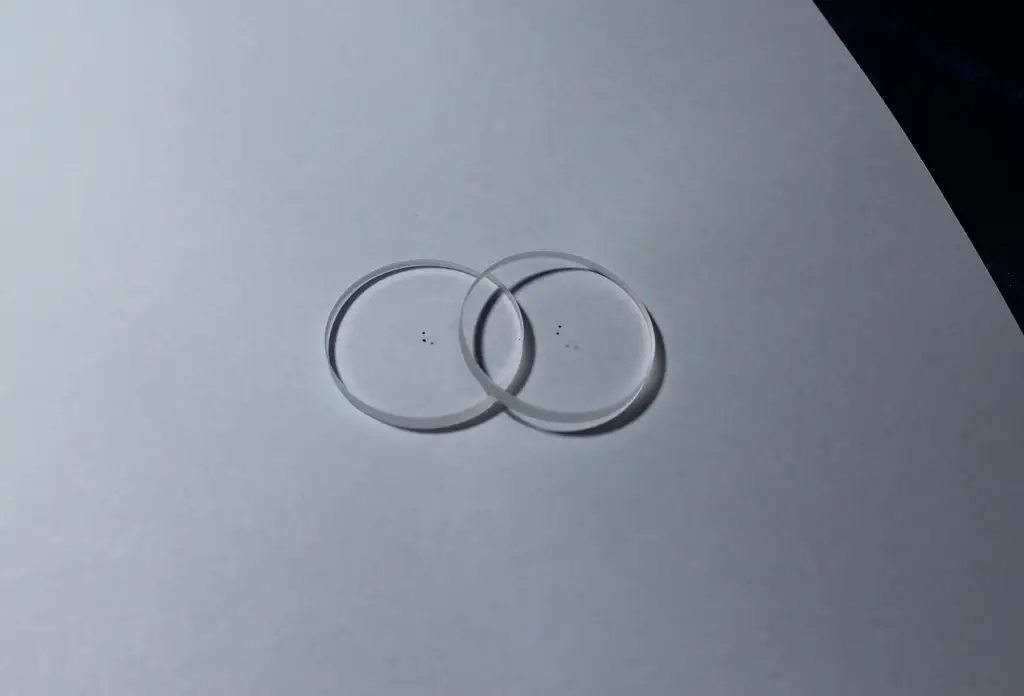

An optical window is a flat, optically transparent material that is used to separate different physical environments while allowing light to pass through without altering its properties. Optical windows are crucial in applications requiring precise light transmission and are designed to be non-absorptive, meaning they do not change the light’s direction, polarization, or wavelength. They serve as protective barriers that prevent external factors, such as dust, moisture, and physical damage, from affecting the delicate optical systems housed within a device.

General Fabrication Specification:

- Materials: High-quality optical glasses such as SiO2, CaF2, BaF2, ZnSe, ZnS, Ge, and Sapphire are typically used, selected based on the specific wavelength and application.

- Dimensions: Ranges include diameters from Ø10 mm to Ø1000 mm, with thicknesses from 0.5 mm to 100 mm, depending on the specific requirements.

- Surface Quality: Achievable surface flatness up to λ/20 and surface quality up to 10-5 (scratch-dig).

- Tolerance: Dimensional tolerance within ±0.005 mm, with wedge angle tolerance up to 30″.

- Coatings: AR coatings, dielectric coatings, and other protective coatings are applied as needed to optimize transmission and minimize reflection across the desired wavelength range.

Fabrication Process and Quality Check:

Bote Optics employs advanced CNC polishing and double-sided polishing machines capable of processing large optical windows up to Ø1000 mm. The manufacturing process involves precision grinding, polishing, and coating under stringent quality controls. Each optical window undergoes thorough inspection using state-of-the-art metrology equipment, such as Zygo interferometers for surface accuracy and spectrophotometers for coating performance. The process ensures that each optical window meets the highest industry standards for optical clarity, durability, and performance.

Application:

Optical windows are widely used in a variety of applications, including laser systems, imaging systems, optical communication, medical devices, and environmental monitoring equipment. They are essential in scenarios where high transmission and minimal optical distortion are critical, such as in scientific instruments, aerospace technology, and high-precision metrology systems.

Why Choose Bote Optics:

Bote Optics stands out for its commitment to excellence in optical window manufacturing. Our production capabilities include processing high-quality optical glasses and applying advanced coatings to meet the specific needs of our clients. With a focus on precision and reliability, Bote Optics delivers optical windows that consistently perform in the most demanding environments. Our extensive experience, coupled with cutting-edge technology, ensures that each optical window is crafted to perfection, providing exceptional optical performance and durability. Whether for industrial, medical, or scientific applications, Bote Optics is your trusted partner for high-quality optical windows.