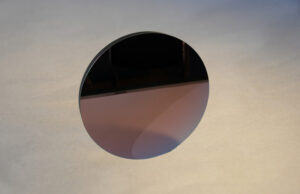

Description of the Components An optical reticle, also known as a reticule, is a critical component used in a variety of optical instruments, such as telescopes, riflescopes, microscopes, and other sighting devices. It consists of a transparent substrate, typically made of glass or plastic, with a finely engraved or printed pattern, grid, or scale. This pattern is used to assist in the measurement, targeting, or alignment of objects within the optical field of view. The design and precision of the reticle are crucial for ensuring accuracy in applications where precise visual measurement or targeting is required.

Optical reticles are available in various configurations, including crosshairs, dot patterns, scales, and custom designs, depending on the specific application. They are designed to work seamlessly with the optical system, providing clear and sharp visuals that enhance the user’s ability to accurately measure or target an object. The choice of reticle design and material depends on the intended use, whether it be for scientific research, military applications, or recreational activities.

General Fabrication Specification

Optical reticles are fabricated with high precision to meet stringent specifications. Below is a table outlining the typical specifications for optical reticles:

| Specification | Detail |

|---|---|

| Substrate Material | Optical-grade glass, plastic |

| Pattern Type | Crosshair, dot, scale, custom |

| Engraving Method | Photolithography, laser engraving, silk-screen printing |

| Line Width Tolerance | ±1 µm to ±10 µm |

| Line Thickness | 5 µm to 50 µm |

| Surface Quality | 40/20 S&D or better |

| Coating Options | Anti-reflective, hard-coating |

| Optical Flatness | λ/10 over clear aperture |

| Clear Aperture | >90% |

| Environmental Durability | Temperature and humidity resistant |

Fabrication Process and Quality Control

The fabrication of optical reticles involves several precise and controlled steps to ensure that the final product meets the required specifications. The process typically begins with the selection of high-quality substrate material, which is then cleaned and prepared for patterning. The pattern is created using photolithography, laser engraving, or silk-screen printing, depending on the design and required precision. Photolithography allows for the creation of highly detailed patterns with fine lines and intricate designs, making it ideal for complex reticles.

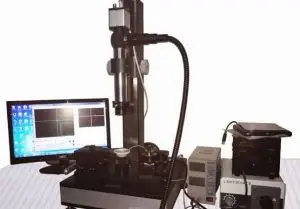

After the pattern is applied, the reticle undergoes a series of quality checks to verify the accuracy of the engraving or printing. These checks include measurements of line width, thickness, and alignment, using high-precision metrology equipment such as microscopes and profilometers. Surface quality is also inspected to ensure there are no defects that could interfere with the optical performance. The reticle may be coated with anti-reflective or hard-coating layers to enhance its durability and optical clarity.

Final inspections include environmental testing to ensure the reticle can withstand the operational conditions it will be exposed to, such as temperature variations and humidity. Only after passing these rigorous tests is the optical reticle deemed ready for integration into the final optical system.

Application

Optical reticles are essential components in a wide range of applications where precision targeting or measurement is required. In military and defense, reticles are used in riflescopes and targeting systems to accurately aim at distant targets. In scientific research, reticles in microscopes allow for precise measurements and comparisons of microscopic structures. Additionally, optical reticles are used in surveying equipment, astronomy, and navigation systems to assist in the accurate alignment and measurement of objects.

The versatility of optical reticles makes them indispensable in any application where accuracy and precision are paramount. Custom reticle designs can be created to meet the specific needs of different industries, ensuring that the optical system performs optimally in its intended application.

Why Choose Bote Optics

Bote Optics is a leader in the design and manufacturing of high-precision optical reticles, offering a wide range of standard and custom reticle solutions to meet the diverse needs of our clients. Our state-of-the-art manufacturing facilities and experienced engineering team ensure that every reticle we produce meets the highest standards of quality and accuracy. With advanced fabrication techniques and rigorous quality control processes, Bote Optics delivers optical reticles that provide superior performance and reliability in even the most demanding environments.

Choosing Bote Optics for your optical reticle needs means partnering with a company committed to innovation, quality, and customer satisfaction. Our expertise in optical engineering and dedication to excellence make us the preferred choice for clients seeking the best in optical components. Whether you need a standard reticle or a custom design, Bote Optics has the capabilities and experience to deliver a product that meets your exact specifications.