Description of the Components: Optical filters are precision components that selectively transmit or block specific wavelengths of light while allowing others to pass through. These filters are essential in various optical systems, where they control the spectral properties of light to enhance imaging, sensing, and detection capabilities. Optical filters are categorized based on their spectral performance, including bandpass, shortpass, longpass, neutral density (ND), and dichroic filters. Each type of filter is designed to meet specific application requirements, making them indispensable in fields ranging from scientific research to industrial and medical imaging.

General Fabrication Specification:

| Type of Coating | Usage | Detail |

|---|---|---|

| Anti-Reflect (AR) | Improve transmission | T up to 95% |

| Mirror | Signal reflection | Ar, Au, Al, Mg coating |

| Bandpass Filters | Control a narrow, well-defined spectral wavelength | Width: 10nm |

| Bandstop Filters / Notch Filters | Reject light of a specified wavelength range | Up to OD6 in the reject area |

| Shortpass & Longpass Filters | Let the signal pass after or before a specific spectral value and stop the remaining | Cut-on/off slope 3 to 5% |

| ND Filters (Neutral Density) | Attenuate an optical signal | Up to OD8 (T=10^8) |

| Dichroic Filter | Split the signal in different wavelengths | Trichroic are also available |

| Metallization Coating (ITO) | Conductive channels (heat/electricity) & welding supports | Metal mask tolerances +/- 0.1mm |

| Anti-Sludge Coating | Protect against dirt deposition | – |

| Water Repellent Coating | Avoid water deposition | – |

| DLC (Diamond Like Carbon) | Hardening for anti-scratch | – |

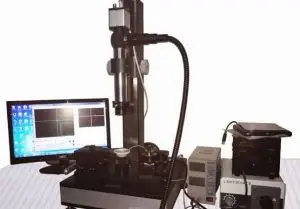

Fabrication Process and Quality Control: The fabrication of optical filters involves high-precision deposition of thin films on glass or other substrates. These thin films are applied through techniques such as sputtering, evaporation, or chemical vapor deposition, each selected based on the filter’s specific requirements. The process involves meticulously controlling the thickness and uniformity of the coatings to ensure precise spectral performance. Quality control includes rigorous testing for transmission, reflection, and absorbance at specified wavelengths. The filters are also tested for environmental durability, including temperature stability, humidity resistance, and abrasion, ensuring they meet stringent optical and mechanical standards.

Applications: Optical filters are used across various applications, including photography, spectroscopy, fluorescence microscopy, and telecommunications. In photography and imaging, filters enhance contrast and color balance. In scientific research, they enable precise wavelength selection for analyzing specific materials or biological samples. In telecommunications, optical filters are used in fiber-optic networks to manage and separate different data channels. These filters are also critical in medical devices, where they facilitate accurate diagnostics and imaging.

Why Choose Bote Optics: Bote Optics is committed to delivering high-performance optical filters tailored to the exacting demands of our clients. With advanced coating technologies and rigorous quality control, we ensure that each filter meets the highest standards of precision and durability. Our expertise in custom filter design allows us to provide solutions that are optimized for your specific applications, whether for industrial, scientific, or medical use. Bote Optics combines innovation with reliability, making us the preferred partner for cutting-edge optical components.