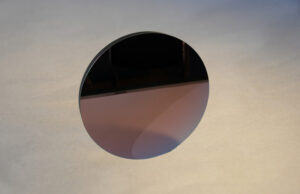

Micro Lens Description Micro lenses are precision-engineered optical components designed for high-performance imaging systems. These lenses are exceptionally small, often utilized in applications where space constraints are critical, such as medical devices, miniature cameras, and fiber-optic systems. Typically, micro lenses are manufactured from high-quality materials like optical glass, fused silica, or sapphire, ensuring durability and superior optical clarity. Their function is to focus or redirect light with high precision, often integrating seamlessly into complex optical assemblies. Due to their minute size, micro lenses are essential in systems requiring minimal distortion and maximum resolution.

General Fabrication Specification Micro lenses are fabricated with meticulous attention to detail, involving advanced optical manufacturing techniques. The dimensional range for these lenses typically spans from sub-millimeter sizes up to several millimeters, with tolerances often within ±0.01 mm to ensure precision. The surface quality is maintained at a high standard, commonly adhering to an S&D rating of 60/40 or better. Clear aperture specifications generally exceed 90%, ensuring minimal optical losses. Additionally, micro lenses can be coated with various anti-reflective (AR) coatings to enhance their performance in specific wavelength ranges, from UV to infrared.

| Specification | Detail |

|---|---|

| Material | Optical Glass, Fused Silica, Sapphire |

| Size | Typically from 0.5mm to 10mm |

| Surface Quality | S&D 60/40 |

| Dimensional Tolerance | ±0.01 mm |

| Clear Aperture | >90% |

| Coatings | Custom AR coatings available |

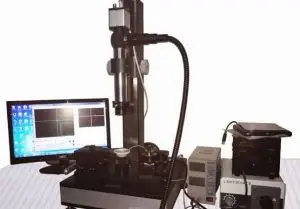

Fabrication Process and Quality Check The fabrication of micro lenses involves precision grinding, polishing, and coating processes, often carried out under controlled environments to maintain stringent quality standards. CNC machines are utilized to shape the lenses, followed by polishing techniques that ensure surface smoothness and optical clarity. Post-fabrication, each micro lens undergoes rigorous inspection using interferometers and other advanced metrology tools to verify surface accuracy, centering, and coating integrity. These quality checks are crucial to guarantee that each lens meets the high-performance criteria required for its intended application.

Application Micro lenses are widely used in various high-tech applications due to their compact size and superior optical performance. In the medical field, they are integral to endoscopic devices and other diagnostic equipment, where precise imaging is critical. In consumer electronics, micro lenses are essential in compact camera modules, optical sensors, and fiber-optic communication systems. Their ability to focus and direct light with minimal aberration makes them invaluable in any application requiring miniature yet highly efficient optical components.

Why Choose Bote Optics Bote Optics specializes in the custom manufacturing of micro lenses, offering unparalleled expertise in precision optics. Our advanced production facilities and rigorous quality control processes ensure that every micro lens we produce meets the highest industry standards. We offer a wide range of customization options, including material selection, coating types, and dimensional specifications, tailored to meet the unique needs of our clients. By choosing Bote Optics, you benefit from our commitment to quality, innovation, and customer satisfaction, ensuring that your optical systems perform at their best.