Light pipes, also known as light guides, are optical components designed to channel light from one location to another with minimal loss. These components work on the principle of total internal reflection, where light is efficiently transmitted through a transparent medium, typically glass or plastic, even around bends and corners. Light pipes are widely used in applications requiring controlled light distribution, such as in backlighting, medical devices, and automotive displays.

General Fabrication Specification

The fabrication of light pipes involves precise control over the material properties, surface quality, and geometric dimensions to ensure optimal light transmission and uniformity. Key specifications include:

| Specification | Detail |

|---|---|

| Material | Optical-grade glass, Acrylic (PMMA), Polycarbonate (PC) |

| Length | Customizable, typically ranges from a few millimeters to over a meter |

| Diameter | 0.5 mm to 20 mm |

| Surface Quality | 40/20 S&D or better |

| Transmission | >90% for visible light |

| Coatings | Anti-reflective coatings available for enhanced performance |

| Tolerances | ±0.01 mm for diameter, ±0.05 mm for length |

Fabrication Process and Quality Control

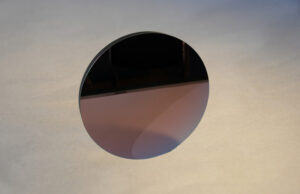

The manufacturing process of light pipes involves several key steps, including precision molding, machining, and polishing. High-quality optical materials are selected to ensure excellent light transmission. The raw material is first shaped using precision CNC machines to achieve the desired geometry. The surfaces are then polished to optical-grade finishes to minimize scattering and ensure efficient light transfer.

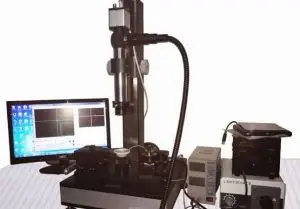

To further enhance performance, anti-reflective coatings may be applied to the surfaces. Quality control is integral to the manufacturing process, with each light pipe undergoing rigorous testing. This includes optical inspections to verify surface quality and dimensional accuracy, as well as light transmission tests to ensure the component meets the specified performance criteria.

Application

Light pipes are versatile components used in a wide range of applications where controlled light delivery is essential. In the automotive industry, they are used in dashboard displays and ambient lighting systems to provide consistent and uniform illumination. In medical devices, light pipes enable precise light delivery in diagnostic instruments and surgical tools. They are also integral to consumer electronics, where they are used to channel light in backlit displays, keypads, and indicator lights.

Why Choose Bote Optics

Bote Optics stands at the forefront of light pipe manufacturing, offering unmatched expertise and advanced production capabilities. Our light pipes are crafted with precision, ensuring optimal performance in even the most demanding applications. We utilize the latest technologies and highest quality materials to produce light pipes that meet stringent industry standards. With our commitment to innovation, quality, and customer satisfaction, Bote Optics is your trusted partner for all your light pipe needs. Whether you require standard or custom solutions, we deliver products that exceed expectations in terms of performance, durability, and reliability.