Dielectric coated mirrors can provide very high reflectivity (reflectivity can exceed 99.8% at the design wavelength).

Bote can provide dielectric mirrors with center wavelengths from 250nm to 2200nm according to customer requirements. When selecting the appropriate medium with high reflectivity, the requirements for the film damage threshold need to be taken into consideration.

UV fused silica substrate

UV fused silica has low thermal expansion and low absorption in the wavelength range from 350 to 1100 nm, making it useful as a base material for ultra-broadband mirrors.

As a result, these mirrors perform better with temperature fluctuations and are more resistant to environmental effects than many other types of metallic and dielectric mirrors used in these wavelength ranges.

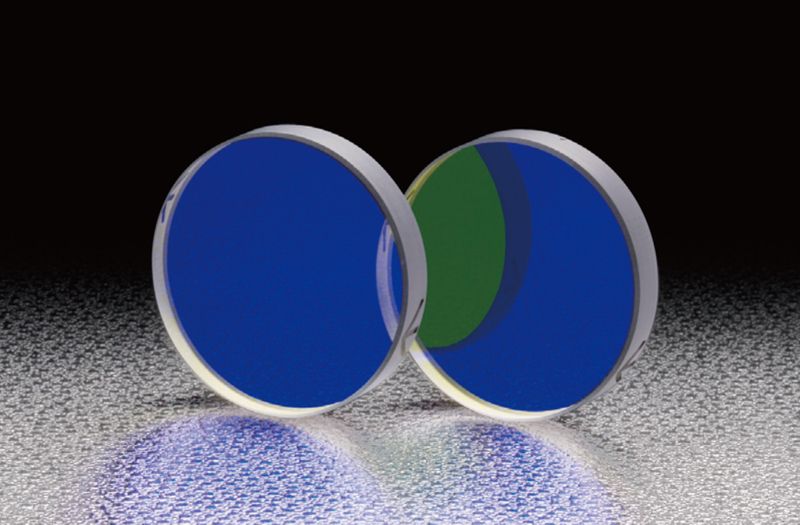

Wide wavelength range, high absolute reflectivity

Using superior ion beam sputter coating technology, very high absolute reflectivity can be achieved over a wide wavelength range. High reflectivity becomes advantageous in low-light conditions, where collecting as much light as possible is crucial.

Depending on the type of coating, Rs, Rp >99% for the wavelength range 350-1100 nm at an angle of incidence of 0-50°.

| Materials | N-BK7, Fused Silica, Borofloat, LAS material |

| Substrate | Flat Window, Spherical Lens, Cylindrical Lens, Rod Lens, Prism is available |

| Dimension Tolerance | ± 0.10 mm |

| Diameter Tolerance | +0/-0.1mm |

| Thickness Tolerance | ± 0.10 mm |

| Clear Aperture | >85% |

| Parallelism | <1 arc minute |

| IRR | Lambda/10 per 1 inch (Substrate) |

| Surface Smoothness | S/D 10-5 or S/D 20-10 (Substrate) |

| Bevel | 0.2mmx45° |

| Coating | R>99.5% for random polarization Or according to the requirement |

| Advantage of Bote | Large AOI( 0-45deg AOI) Broadband(400-750nm/750-1100nm/1280-1600nm) High laser damage threshold |