Advanced Optical Coating Techniques for Enhanced Performance and Durability

Bote Optics Singapore offers cutting-edge optical coating solutions, utilizing advanced thin-film technologies to optimize the performance, durability, and precision of optical components across diverse applications.

Precision in Optical Coating Technology

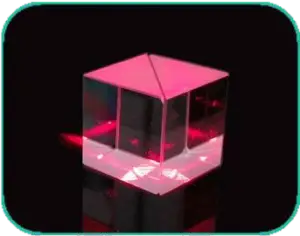

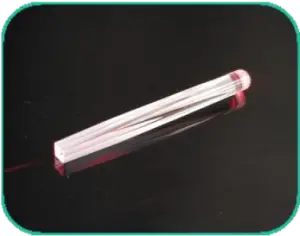

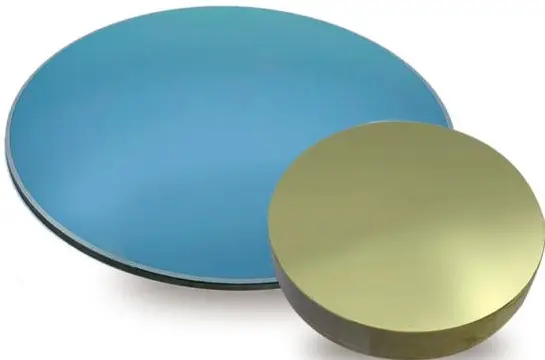

At Bote Optics Singapore, precision is at the heart of our optical coating technology. We understand that even the slightest variation in coating thickness or uniformity can significantly impact the performance of optical components. Our state-of-the-art coating facilities are equipped with advanced deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), ensuring that every optical coating we produce meets the highest standards of accuracy and consistency. These techniques allow us to apply coatings with exceptional uniformity, tailored to the specific requirements of each application, whether for anti-reflective, high-reflective, or beam-splitting coatings.

Customized Coating Solutions for Diverse Applications

Bote Optics Singapore excels in providing customized coating solutions that meet the unique demands of various industries, including aerospace, medical imaging, telecommunications, and defense. Our expertise in optical thin-film coatings enables us to offer a wide range of coatings, each designed to optimize the performance of optical components in specific environments. For instance, our anti-reflective coatings significantly reduce surface reflections, enhancing the clarity and efficiency of imaging systems. Meanwhile, our dielectric and metallic coatings are engineered to withstand harsh environmental conditions, ensuring long-term durability and reliability in even the most demanding applications.

Advanced Materials and Multi-Layer Coating Techniques

The selection of coating materials is crucial to achieving the desired optical properties, and at Bote Optics Singapore, we employ a diverse range of advanced materials to create high-performance coatings. From fluoride-based compounds for UV applications to oxides and metals for infrared and visible spectra, our coatings are designed to meet specific spectral requirements. Additionally, our multi-layer coating techniques enable us to create complex coatings that combine different materials to achieve specific optical effects, such as broad-spectrum anti-reflective coatings or narrow-band filters. Each layer is meticulously designed and applied, ensuring optimal performance and minimal loss.

Rigorous Testing and Quality Assurance

Quality assurance is a critical component of Bote Optics Singapore’s optical coating process. We utilize a comprehensive range of testing methods, including spectrophotometry, interferometry, and environmental testing, to verify the performance and durability of our coatings. These tests ensure that each coated component not only meets but exceeds the specified optical and environmental requirements. Our commitment to rigorous testing and quality control guarantees that our clients receive coatings that deliver consistent, reliable performance in their optical systems, whether in laboratory settings or real-world applications.

Components Capabilities Show