In today’s fast-paced technological landscape, precision is paramount in manufacturing processes, especially when it comes to optics. Optical Processing, a critical component in the production of high-performance optical elements, ensures that these components meet the stringent demands of various industries, from medical imaging to aerospace. At Bote Optics Singapore, we pride ourselves on our expertise in Optical Processing, combining state-of-the-art technology with meticulous craftsmanship to deliver unparalleled quality in every product. This article explores the methodologies, steps, and advanced techniques that make Optical Processing at Bote Optics Singapore stand out.

The Importance of Precision in Optical Processing

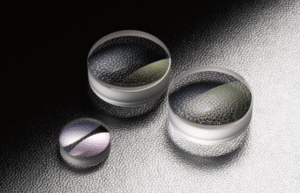

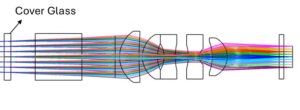

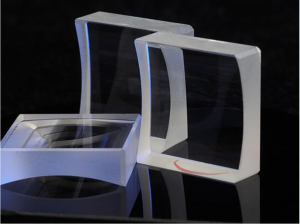

Optical components are the backbone of many advanced systems, where even the slightest deviation can lead to significant performance issues. Whether it’s lenses, mirrors, or prisms, the accuracy of these components directly impacts the overall functionality of optical systems. This is where Optical Processing plays a crucial role. The goal is to achieve surfaces with minimal imperfections, exact dimensions, and precise curvature, which are essential for optimal light transmission and reflection.

At Bote Optics Singapore, our Optical Processing techniques are designed to meet the highest standards of precision. We understand that every component must be crafted to perfection to ensure it performs flawlessly in its intended application. Our commitment to quality and precision drives us to continuously refine our processes, keeping us at the forefront of the industry.

Key Steps in Optical Processing

Material Selection and Preparation

The foundation of any high-quality optical component begins with the selection of the right material. Depending on the application, materials such as optical glass, fused silica, or crystals like sapphire and silicon are chosen for their unique properties, including refractive index, transmission, and durability. At Bote Optics Singapore, we carefully evaluate the material properties to ensure they align with the specific requirements of the final product.

Once the material is selected, it undergoes a rigorous preparation process. This includes cutting and shaping the raw material into blanks that approximate the final component’s dimensions. The precision in this initial step is crucial, as it sets the stage for the subsequent processing stages.

Grinding and Polishing

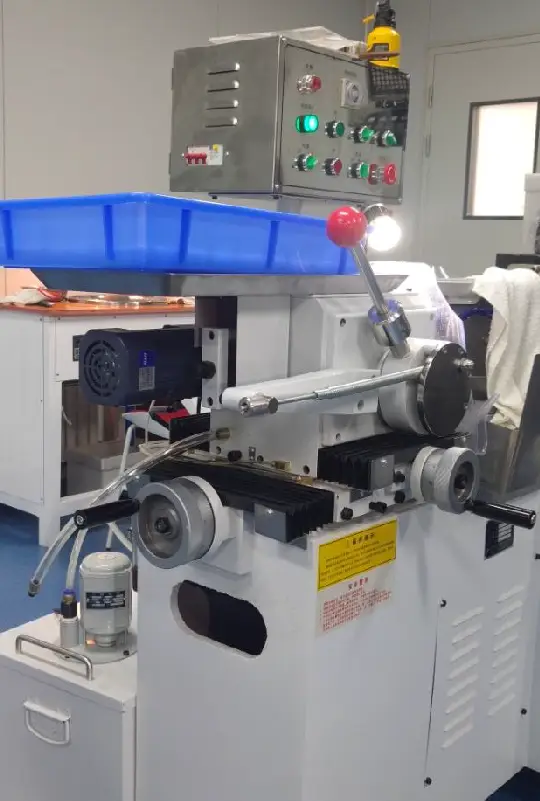

Grinding is the first major step in shaping the optical component. This process involves removing material from the surface to achieve the desired shape and size. At Bote Optics Singapore, we use advanced CNC grinding machines that allow for high precision and control, ensuring that the components are shaped to exact specifications.

Polishing follows grinding and is arguably the most critical step in Optical Processing. The goal of polishing is to achieve a smooth, defect-free surface that meets strict optical standards. Our polishing techniques involve the use of fine abrasives and polishing agents, applied in a controlled environment to minimize surface imperfections such as scratches and pits. The result is an optical surface that ensures optimal light transmission and reflection, essential for high-performance optical systems.

Coating and Inspection

Once the optical surface is polished to perfection, it often requires a coating to enhance its performance. Coatings such as anti-reflective, dielectric, or metallic are applied to improve light transmission, reduce glare, or protect the surface from environmental factors. Bote Optics Singapore employs advanced coating technologies that ensure uniform application and long-lasting durability.

After coating, each optical component undergoes a rigorous inspection process. Using interferometry, surface profilometry, and other precision measurement techniques, we verify that the component meets all specified tolerances. This final inspection is critical to ensuring that every product leaving our facility is of the highest quality.

Methodologies and Advanced Techniques

At Bote Optics Singapore, we leverage a combination of traditional craftsmanship and modern technology in our Optical Processing. Our methodologies are rooted in decades of experience, but we continuously integrate the latest advancements to stay ahead in the industry.

- Computer-Aided Design (CAD): We utilize CAD software to design and simulate optical components before they are manufactured. This allows us to predict performance and make adjustments early in the process.

- CNC Machining: Our CNC machines are capable of producing complex optical shapes with high precision. This technology allows for greater consistency and repeatability in manufacturing.

- Interferometric Testing: Interferometry is used to measure the surface quality of optical components with extreme accuracy. This technique helps us identify and correct any imperfections before the final product is delivered to the client.

Why Choose Bote Optics Singapore for Optical Processing?

Bote Optics Singapore stands out in the field of Optical Processing due to our unwavering commitment to quality, precision, and innovation. Our advanced facilities and experienced team enable us to handle complex projects with ease, delivering optical components that meet the highest standards.

Whether you require custom-designed lenses, mirrors, or other optical elements, Bote Optics Singapore has the expertise and technology to meet your needs. We invite you to explore our services and see how our Optical Processing capabilities can enhance your optical systems. Contact us today to learn more or to discuss your specific requirements. Let Bote Optics Singapore be your trusted partner in precision optics.