In the fast-evolving field of optics, efficiency in both design and manufacturing processes is crucial for delivering high-quality products that meet stringent industry standards. At Bote Optics Singapore, we recognize that streamlining Optical Manufacturing is essential to achieving cost-effective, reliable, and scalable solutions. This article explores the key strategies and methodologies we employ to optimize the design-to-manufacturing workflow, ensuring that our clients receive top-tier optical components and systems tailored to their specific needs.

The Importance of Streamlining Optical Manufacturing

Optical Manufacturing involves the intricate process of transforming design concepts into tangible, functional optical components. This journey from design to production is often complex, involving multiple stages where precision and accuracy are paramount. Streamlining these processes not only reduces costs and production times but also minimizes the risk of errors, ensuring that the final product meets the desired specifications.

At Bote Optics Singapore, we approach Optical Manufacturing with a focus on efficiency and precision. Our integrated design and manufacturing teams work collaboratively to ensure that each stage of the process is optimized for success. This collaborative approach allows us to anticipate potential challenges and address them proactively, ultimately leading to a more efficient production cycle.

Key Steps in Streamlined Optical Manufacturing

- Early Design ConsiderationsThe foundation of streamlined Optical Manufacturing begins with careful consideration during the design phase. At Bote Optics Singapore, we emphasize the importance of designing with manufacturability in mind. This involves selecting materials, tolerances, and geometries that are not only optimal for the optical performance but also feasible within the constraints of manufacturing processes.Our design engineers work closely with the manufacturing team to ensure that the design specifications align with production capabilities. This early collaboration helps in identifying potential issues that could arise during manufacturing, such as material limitations or complex geometries, allowing for adjustments to be made before the design is finalized.

- Simulation and PrototypingSimulation plays a critical role in the design phase, allowing our engineers to predict how the optical system will perform in real-world conditions. By using advanced optical design software, Bote Optics Singapore can simulate various scenarios and make data-driven decisions to optimize the design. These simulations help in refining the design, reducing the need for costly and time-consuming iterations during manufacturing.Once the design is optimized, prototyping serves as the next crucial step in the process. Prototyping allows us to create a physical model of the design, which can be tested and evaluated for performance. This step is vital for identifying any unforeseen issues and making necessary adjustments before moving to full-scale production.

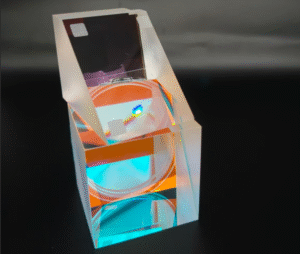

- Optimized Manufacturing ProcessesWith a refined design and validated prototype, Bote Optics Singapore focuses on optimizing the manufacturing process. This includes selecting the most appropriate manufacturing techniques, such as precision machining, molding, or coating, depending on the specific requirements of the optical component. Our advanced manufacturing facilities are equipped with state-of-the-art machinery that allows us to produce high-quality optics with tight tolerances and excellent surface quality.During the manufacturing process, continuous monitoring and quality control are essential to ensuring that each component meets the required specifications. At Bote Optics Singapore, we employ rigorous inspection techniques, including interferometry and surface profilometry, to verify the accuracy and quality of the optical components. This commitment to quality ensures that our products are not only functional but also durable and reliable.

Methodologies for Success in Optical Manufacturing

- Design for Manufacturability (DFM): At Bote Optics Singapore, DFM principles are integral to our design process. By considering the manufacturing constraints early in the design phase, we can simplify the production process, reduce costs, and ensure that the final product meets the desired performance criteria.

- Iterative Testing and Validation: Continuous testing and validation are key to our approach, allowing us to refine designs based on real-world performance data. This iterative process ensures that any potential issues are addressed before the product reaches the final production stage.

- Collaborative Engineering: Collaboration between design and manufacturing teams is crucial to streamlining Optical Manufacturing. At Bote Optics Singapore, our engineers work together to ensure that the transition from design to production is seamless, reducing the risk of miscommunication and errors.

Why Choose Bote Optics Singapore for Your Optical Manufacturing Needs?

Bote Optics Singapore is committed to delivering high-quality optical components and systems through a streamlined, efficient manufacturing process. Our expertise in Optical Manufacturing, coupled with our advanced facilities and dedicated team, ensures that we can meet the diverse needs of our clients, from concept to final production.

Whether you are developing a new optical system or optimizing an existing design, Bote Optics Singapore is your trusted partner. Our focus on precision, quality, and efficiency sets us apart, making us the preferred choice for clients across various industries. Contact us today to learn more about our Optical Manufacturing capabilities and how we can help bring your optical innovations to life.