In the realm of advanced optics, the ability to precisely control light is crucial for a wide range of applications, from imaging systems to display technologies. One of the most effective tools for achieving this control is the Micro Prism, a specialized optical component designed to manipulate light with extraordinary precision. At Bote Optics Singapore, we have mastered the art of designing and manufacturing Micro Prism components that deliver unparalleled performance in even the most demanding applications. This article explores our approach to Micro Prism design and fabrication, highlighting the methodologies and techniques that set Bote Optics Singapore apart.

The Role of Micro Prisms in Optical Systems

Micro Prisms are tiny optical elements that bend, refract, or reflect light in specific ways to achieve desired outcomes in an optical system. Due to their small size and precise angles, Micro Prisms are used in applications where traditional optical components would be too large or imprecise. These components are essential in various industries, including telecommunications, medical devices, and aerospace, where they are used to steer light, split beams, or correct optical paths.

At Bote Optics Singapore, we understand the critical role that Micro Prisms play in modern optical systems. Our expertise in optical design and fabrication allows us to create Micro Prisms that meet the highest standards of precision and performance. Whether it’s for enhancing image clarity, improving signal transmission, or increasing the efficiency of a light path, our Micro Prisms are engineered to deliver optimal results.

Steps and Methodologies in Micro Prism Design

Initial Design and Requirement Analysis

The process of creating high-performance Micro Prism components begins with a thorough understanding of the client’s requirements. At Bote Optics Singapore, we work closely with our clients to define the specifications of the Micro Prism, including its size, angle, and the material from which it will be made. This initial phase is crucial for ensuring that the final product will meet the specific needs of the application.

Key considerations during this stage include the refractive index of the material, the angle of incidence, and the desired light path. By carefully analyzing these factors, we can develop a design that maximizes the effectiveness of the Micro Prism in its intended application.

Precision Fabrication Techniques

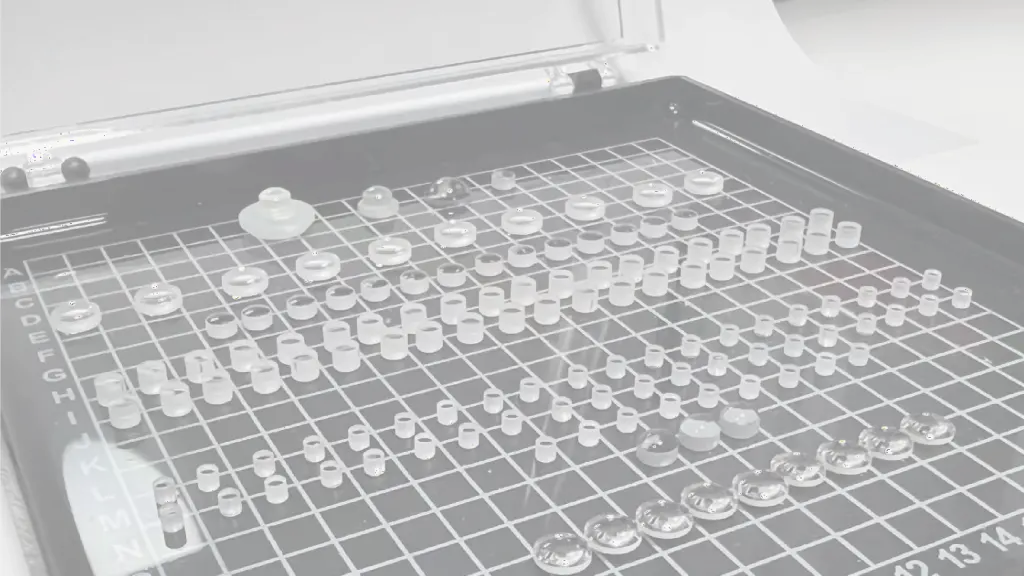

Once the design is finalized, the next step is fabrication. Micro Prism fabrication requires an extraordinary level of precision, as even the smallest deviation in angle or surface quality can significantly impact performance. At Bote Optics Singapore, we employ advanced fabrication techniques such as precision diamond turning, micro-milling, and lithography to create Micro Prisms with exacting tolerances.

Our state-of-the-art facilities are equipped with the latest machinery and technology, allowing us to produce Micro Prisms with sharp angles, smooth surfaces, and accurate dimensions. Throughout the fabrication process, we maintain strict quality control to ensure that each component meets the specified requirements.

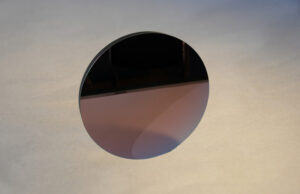

Coating and Finishing

After the Micro Prism is fabricated, it often undergoes additional processing to enhance its performance. This may include the application of anti-reflective coatings, dielectric coatings, or metallic coatings, depending on the needs of the application. Coatings are applied using advanced deposition techniques that ensure uniform coverage and long-lasting durability.

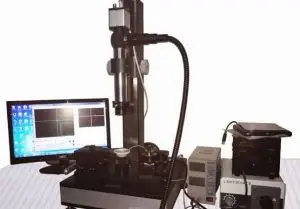

The finishing process also includes rigorous inspection and testing. At Bote Optics Singapore, we use interferometry, surface profilometry, and other precision measurement techniques to verify the quality of each Micro Prism. This ensures that the final product not only meets but exceeds industry standards.

Applications of Micro Prism Components

Micro Prisms are used in a wide variety of applications across different industries. Some of the key applications include:

- Telecommunications: Micro Prisms are used in fiber optic systems to direct light signals with high precision, enabling faster and more reliable communication.

- Medical Imaging: In medical devices, Micro Prisms help to control light paths, improving the clarity and accuracy of imaging systems.

- Aerospace and Defense: Micro Prisms are utilized in targeting systems, navigation equipment, and other critical technologies where precise light control is essential.

- Consumer Electronics: These components are also found in display technologies, where they enhance image quality and viewing angles.

Why Choose Bote Optics Singapore for Micro Prism Solutions?

Bote Optics Singapore is a leader in the design and manufacturing of Micro Prism components. Our commitment to precision, innovation, and quality ensures that we deliver optical solutions that meet the most demanding requirements. With our advanced capabilities and dedicated team of experts, we are equipped to handle projects of any complexity, providing our clients with the best possible results.

Whether you need a custom Micro Prism for a specific application or are looking to optimize an existing optical system, Bote Optics Singapore is your trusted partner. Contact us today to learn more about our Micro Prism capabilities and how we can help you achieve precision light control in your optical systems. Let Bote Optics Singapore be your go-to source for all your optical needs.

4o