Infrared optics play a critical role in various industries, from surveillance to scientific research, where capturing clear and accurate images in low-light or thermal conditions is essential. At Bote Optics Singapore, we specialize in advanced Infrared Lens Design, focusing on creating lenses that offer both high performance and a wide field of view (FOV). This article explores a comprehensive approach to enhancing Infrared Lens Design, detailing the steps, methodologies, and results that highlight the capabilities and strengths of Bote Optics Singapore.

The Challenge: Achieving a Wide Field of View in Infrared Lens Design

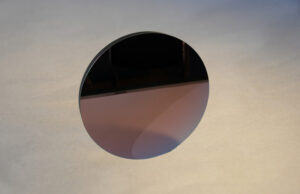

Designing an infrared lens that provides a wide field of view while maintaining image quality presents several challenges. Infrared wavelengths, typically ranging from 700 nm to 14,000 nm, require specialized materials and coatings to ensure proper light transmission and minimal aberrations. Additionally, achieving a wide FOV without sacrificing resolution or introducing significant optical distortions is a complex task that requires a deep understanding of optical physics and advanced design techniques.

At Bote Optics Singapore, we were tasked with developing an infrared lens that could deliver superior imaging performance across a broad field of view. Our goal was to create a lens that could be used in applications such as thermal imaging, security surveillance, and environmental monitoring, where wide coverage and clarity are paramount.

The Approach: Advanced Methodologies in Infrared Lens Design

- Initial Requirements Analysis and Design Specifications The first step in our Infrared Lens Design process involved a thorough analysis of the project requirements. This included defining the desired FOV, determining the appropriate infrared wavelength range, and understanding the environmental conditions in which the lens would be used. By collaborating closely with our client, we were able to establish clear design specifications that guided the development process.Key considerations during this phase included the selection of optical materials with high transmission rates in the infrared spectrum, as well as the need for coatings that could enhance durability and performance in harsh environments. At Bote Optics Singapore, our expertise in material science and optical coatings allowed us to identify the best possible materials for the lens, ensuring that it would meet the stringent requirements of the application.

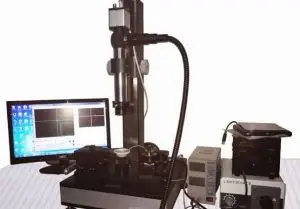

- Optical Design and Simulation With the design specifications in hand, our team proceeded to the optical design phase. Using advanced optical design software, we created a detailed model of the lens system, simulating how it would perform under various conditions. This stage involved optimizing the lens elements to minimize aberrations, such as spherical and chromatic aberrations, which can degrade image quality in infrared optics.One of the critical challenges in Infrared Lens Design is managing the thermal expansion of materials, which can lead to focus shifts and distortions. To address this, Bote Optics Singapore employed a combination of materials with low thermal expansion coefficients and robust mechanical design to ensure that the lens maintained its performance across a wide temperature range. The use of aspheric lens elements also played a key role in achieving the desired wide FOV without compromising on image clarity.

- Prototyping and Testing After finalizing the optical design, we moved on to the prototyping phase. Bote Optics Singapore’s state-of-the-art manufacturing facilities allowed us to produce high-precision prototypes that closely matched the design specifications. These prototypes were subjected to rigorous testing to evaluate their performance in real-world conditions.Testing involved assessing the lens’s ability to capture clear images across the entire field of view, even at the extreme edges. We also measured the lens’s thermal stability, ensuring that it could operate effectively in varying environmental conditions. The results of these tests were used to make any necessary adjustments to the design before moving to full-scale production.

Results and Impact: Delivering High-Performance Infrared Lenses

The optimized Infrared Lens Design developed by Bote Optics Singapore successfully met all the project’s objectives. The lens delivered a wide field of view with minimal optical distortions, providing clear and accurate imaging across the entire FOV. Its performance remained stable across a broad range of temperatures, making it suitable for use in various industrial and environmental applications.

The success of this project highlights Bote Optics Singapore’s capabilities in Infrared Lens Design, demonstrating our ability to tackle complex optical challenges and deliver solutions that meet the highest standards of quality and performance. Our comprehensive approach, from initial design to final testing, ensures that every lens we produce is tailored to the specific needs of our clients.

Why Choose Bote Optics Singapore for Infrared Lens Design?

Bote Optics Singapore is a leader in the field of Infrared Lens Design, offering advanced optical solutions that are both innovative and reliable. Our team of experts combines deep technical knowledge with cutting-edge technology to deliver lenses that excel in demanding applications. Whether you need a custom-designed lens for a specific project or want to optimize an existing optical system, Bote Optics Singapore is your trusted partner.

Contact us today to learn more about our Infrared Lens Design capabilities and discover how we can help you achieve superior performance in your optical applications. Let Bote Optics Singapore be your guide to excellence in infrared optics.