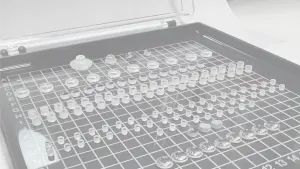

Bote’s plate beam splitter is coated with a dielectric beam splitter on one side. When non-polarized light is incident on the coating surface at an incident angle of 45 degrees, a split ratio of 30:70 can be obtained in the visible light band (450 nm-650 nm). Backside reflection causes interference of reflected light.

In applications sensitive to these phenomena, consider using a non-polarizing beamsplitter cube. Bote chooses to use soda-lime glass to make flat beamsplitters in various sizes.

| Material | N-BK7 |

| Dimension Tolerance | ± 0.20 mm |

| Diameter Tolerance | +0/-0.2mm |

| Thickness Tolerance | ± 0.20 mm |

| Clear Aperture | >85% |

| Parallelism | <1 arc minute |

| Surface Quality | lambda/4 per 1 inch @632.8nm |

| Surface Smoothness | S/D 60-40 |

| Bevel | 0.2mmx45° |

| Coating | Angle of Incident 45 degree S1 Surface Dielectric Coating T/R±5%@Wavelength S2 Surface AR-V coating@wavelength T=(Ts+Tp)/2, R=(Rs+Rp)/2 T/R = 90/10, 80/20, 70/30, 75/25, 50/50, 25/75, 30/70, 20/80, 10/90 is available |

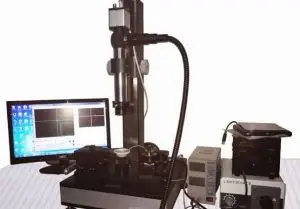

Non-polarizing beam splitting application cases

- Beam splitting and combining

Non-polarizing beam splitting is used to split the incident light into two or more beams with the same wavelength. The reflected or transmitted beam is specified by the splitting ratio, which is the ratio of reflected light to transmitted light (R:T). Most non-polarizing beam splitters can be divided into two types: plate beamsplitters and cubic beamsplitters.

- Interference applications

In interference applications, non-polarizing beam splitters are often used to split and combine monochromatic light, and ultimately form interference fringes with stable intensity distribution on the camera. Changes in optical path difference or interference fringes are used to adjust size, Detection of physical quantities such as topography, roughness, refractive index, etc.

- Beam monitoring

In beam monitoring applications, non-polarizing beam splitters with different light splitting ratios (such as 1:99, 10:90, etc.) are often used to split the light, and the low-power emergent light is used as monitoring light to exclude light sources or the environment influence, or used in feedback systems to monitor changes in light beams to facilitate real-time adjustment of the system.

- Bundle application

The laser display system is mainly composed of three primary color laser light sources, optical engines and screens. The optical engine is mainly composed of red, green and blue light valves, beam combining X prisms, projection lenses and drive light valves.

The light valve drive generates small pictures corresponding to red, green and blue colors on the light valve, and then introduces the three colors respectively. Color laser illumination is projected onto the screen to produce a full-color display image.

The light valve and driving source can be various micro display systems, such as LCD, LCoS, DMD, GLV, etc. Its operation is shown in the figure below: red, green, and blue lasers are incident on the corresponding light valve after beam expansion, shimming, and decoherence respectively.

Image modulation signals are added to the light valves. After modulation, the three-color laser The laser light is combined by the X prism and then enters the projection objective lens. Finally, it is projected onto the screen through the projection lens to obtain the laser display image.