In today’s fast-paced technological landscape, Reverse Optical Engineering has become an invaluable tool for innovation, allowing companies to deconstruct and analyze existing optical systems to enhance, replicate, or innovate upon them. At Bote Optics Singapore, we pride ourselves on our cutting-edge expertise in Reverse Optical Engineering, offering a meticulous, step-by-step approach that ensures precise replication and optimization of optical components and systems.

Understanding Reverse Optical Engineering

Reverse Optical Engineering involves a detailed process where existing optical designs are analyzed to understand their functionality, materials, and performance. This technique is essential for various applications, such as replicating discontinued products, improving existing designs, or understanding competitor technologies. Bote Optics Singapore excels in this field, offering tailored solutions that meet the specific needs of our clients.

The Reverse Optical Engineering Process at Bote Optics Singapore

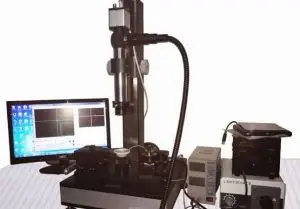

- Initial Analysis and Assessment: The first step in Reverse Optical Engineering is a comprehensive analysis of the optical system. Our experts at Bote Optics Singapore begin by thoroughly understanding the system’s design, including the materials used, the geometries of the optical elements, and the intended application. This stage is crucial for identifying the key parameters that influence the system’s performance.

- System Deconstruction and Modeling: After the initial assessment, the optical system is carefully deconstructed. Each component is examined to understand its role in the overall design. Our team then creates detailed models of the optical elements using advanced software tools. These models allow us to simulate the system’s behavior and identify areas for improvement or optimization.

- Design Optimization and Enhancement: With a clear understanding of the original design, Bote Optics Singapore’s engineers focus on optimizing the system. This may involve modifying the optical layout, selecting better materials, or enhancing the coatings to improve performance. Our goal is not just to replicate the system but to enhance it, ensuring that it meets or exceeds modern standards.

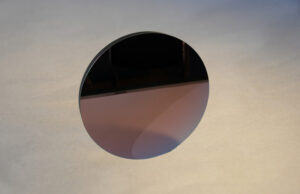

- Prototyping and Testing: Once the design is optimized, we move on to prototyping. Bote Optics Singapore utilizes state-of-the-art fabrication techniques to create high-precision prototypes. These prototypes are rigorously tested to ensure they meet the desired specifications. Our testing process includes evaluating optical performance, durability, and environmental stability.

- Final Production and Validation: After successful prototyping, the system is ready for full-scale production. Bote Optics Singapore ensures that the final product is manufactured to the highest standards of quality. Each component is carefully validated to confirm that it meets the required performance criteria.

Why Choose Bote Optics Singapore for Reverse Optical Engineering?

Bote Optics Singapore is a leader in Reverse Optical Engineering, offering unparalleled expertise and advanced technological capabilities. Our comprehensive approach ensures that every project is handled with precision and care, from initial analysis to final production. We are committed to delivering solutions that not only meet but exceed your expectations.

Whether you need to replicate an existing optical system, improve its performance, or gain insights into a competitor’s design, Bote Optics Singapore is your trusted partner. Contact us today to learn more about our services or to discuss your specific needs. Let us help you harness the power of Reverse Optical Engineering to drive innovation and success in your projects.